The Estate - Bevendean History Project

Brief History of Brighton Sheet Metal

Brighton Sheet Metal

"Over 100 years of manufacturing in Brighton"

"Over 100 years of manufacturing in Brighton"

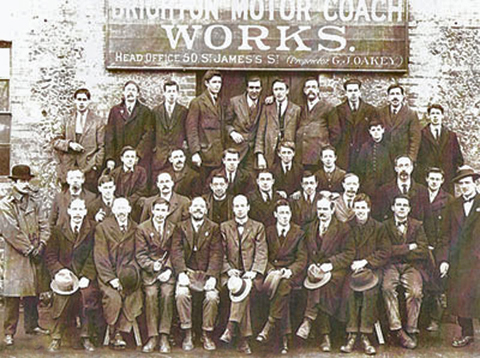

The company originally worked from

premises in the St James' Street/Devonshire Place area of Brighton

where they existed in a variety of guises before moving to Lower

Bevendean in the early sixties. They became one of the leading UK

specialists in precision, CNC (Computer Numerical Control) forming and

fabrications for a wide range of industries making the boxes to house

computers, electronic and telecom equipment, medical equipment,

compressors and generators.

The company employed about 100 people. The parent company once owned a series of well-known local companies including Ranalah Gates, Ranalah Steel Moulds, Engineer's Supplies, Brouralay Tools, Ranalah Architectural Metalwork and at one time employed more than 300 people in premises in Brighton, Hollingbury, Portslade, Newhaven and Wiltshire. Products have included wrought iron gates and balustrading, the Ranalah Wheeling machine, parts for the Isetta "bubble" car, mud guards for tanks, a range of space heaters and the Nippy rotary dryer.

Changing tastes and technologies resulted in several major restructuring of the company particularly in the late 1980s and again in the mid 1990's when the company concentrated its efforts on fabrication work at its Lower Bevendean site, expanding into the old Harrimonde factory in 1997.

A review of historic figures shows that the company has tracked the fate of British industry pretty closely a continuous cycle of boom followed by recession (including a bankruptcy in 1947), the telecom crash of 2000, and global competition. Employment, health and safety and environmental legislation have all been taken in their stride and they have responded to market needs and trends as required: Direct Line Feed, Just In Time, KanBan stocks, Lean Manufacturing etc. Providing work to world class companies kept BSM on its toes in terms of innovation and those visiting cannot but be impressed by the skills and facilities demonstrated by what was once a "back street" business amongst the Victorian slums of east Brighton.

By the 21st century the company was equipped with the latest automated cutting and forming equipment, and weathered the recession earlier this century, global competition and increasing material costs. The Managing Director, Bill Taylor said that he believed the reason for their continuing success was a "…willingness to embrace change, a dedicated, skilled and loyal workforce and an ongoing investment programme aimed at lowering costs by increasing productivity, efficiency and skills...". He also noted that a deliberate policy of seeking customers from a wide spectrum of industries has offered a degree of protection in difficult times." The company was nomination for a variety of awards in recent years including Manufacturer of the Year, Export Growth, Responsible Business, Business Growth demonstrates their constant strive for excellence in all aspects of the business. Having held ISO accreditation for many years, the company achieved the ISO 9000:2008 Quality certification in early 2010.

BSM trained a multi-skilled workforce able to react to customers' varied demands and increasingly short lead times, and in 2010 took on three Engineering Apprentices, the first for many years. This was to be a rolling programme reinforcing the need for a multi-skilled workforce able to respond quickly to the ever changing production demands that were synonymous with life at Brighton Sheet Metal.

The company prided itself on the number of long serving employees and over the years has employed many generations of the same local families. Malcolm Holman the Technical Sales Director, joined BSM as an Apprentice Toolmaker in late 1960 and so recently celebrated 50 years with the company. Malcolm said "50 years have flown by, being a sub-contract company there is never a dull moment, and to see the company still thriving after all these years is very satisfying."

The company got into financial difficulty and Moorfields were appointed as the administrators to wind up the company on the 5 March 2018. The firm closed with the loss of over 50 jobs and the machinery was sold off once all the outstanding orders had been completed.

Information from the company’s website following the closure in 2018.

The company employed about 100 people. The parent company once owned a series of well-known local companies including Ranalah Gates, Ranalah Steel Moulds, Engineer's Supplies, Brouralay Tools, Ranalah Architectural Metalwork and at one time employed more than 300 people in premises in Brighton, Hollingbury, Portslade, Newhaven and Wiltshire. Products have included wrought iron gates and balustrading, the Ranalah Wheeling machine, parts for the Isetta "bubble" car, mud guards for tanks, a range of space heaters and the Nippy rotary dryer.

Changing tastes and technologies resulted in several major restructuring of the company particularly in the late 1980s and again in the mid 1990's when the company concentrated its efforts on fabrication work at its Lower Bevendean site, expanding into the old Harrimonde factory in 1997.

A review of historic figures shows that the company has tracked the fate of British industry pretty closely a continuous cycle of boom followed by recession (including a bankruptcy in 1947), the telecom crash of 2000, and global competition. Employment, health and safety and environmental legislation have all been taken in their stride and they have responded to market needs and trends as required: Direct Line Feed, Just In Time, KanBan stocks, Lean Manufacturing etc. Providing work to world class companies kept BSM on its toes in terms of innovation and those visiting cannot but be impressed by the skills and facilities demonstrated by what was once a "back street" business amongst the Victorian slums of east Brighton.

By the 21st century the company was equipped with the latest automated cutting and forming equipment, and weathered the recession earlier this century, global competition and increasing material costs. The Managing Director, Bill Taylor said that he believed the reason for their continuing success was a "…willingness to embrace change, a dedicated, skilled and loyal workforce and an ongoing investment programme aimed at lowering costs by increasing productivity, efficiency and skills...". He also noted that a deliberate policy of seeking customers from a wide spectrum of industries has offered a degree of protection in difficult times." The company was nomination for a variety of awards in recent years including Manufacturer of the Year, Export Growth, Responsible Business, Business Growth demonstrates their constant strive for excellence in all aspects of the business. Having held ISO accreditation for many years, the company achieved the ISO 9000:2008 Quality certification in early 2010.

BSM trained a multi-skilled workforce able to react to customers' varied demands and increasingly short lead times, and in 2010 took on three Engineering Apprentices, the first for many years. This was to be a rolling programme reinforcing the need for a multi-skilled workforce able to respond quickly to the ever changing production demands that were synonymous with life at Brighton Sheet Metal.

The company prided itself on the number of long serving employees and over the years has employed many generations of the same local families. Malcolm Holman the Technical Sales Director, joined BSM as an Apprentice Toolmaker in late 1960 and so recently celebrated 50 years with the company. Malcolm said "50 years have flown by, being a sub-contract company there is never a dull moment, and to see the company still thriving after all these years is very satisfying."

The company got into financial difficulty and Moorfields were appointed as the administrators to wind up the company on the 5 March 2018. The firm closed with the loss of over 50 jobs and the machinery was sold off once all the outstanding orders had been completed.

Information from the company’s website following the closure in 2018.

Photographs of the Brighton Sheet Metal Company on 30 July 2014