Churches - Bevendean History Project

St Wilfrid's, Elm Grove - Construction of the New ChurchThe following article first appeared in the Journal of The Royal Institute of British Architects on 13 January 1934.

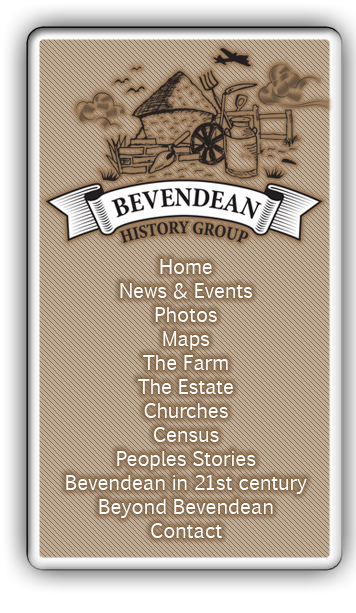

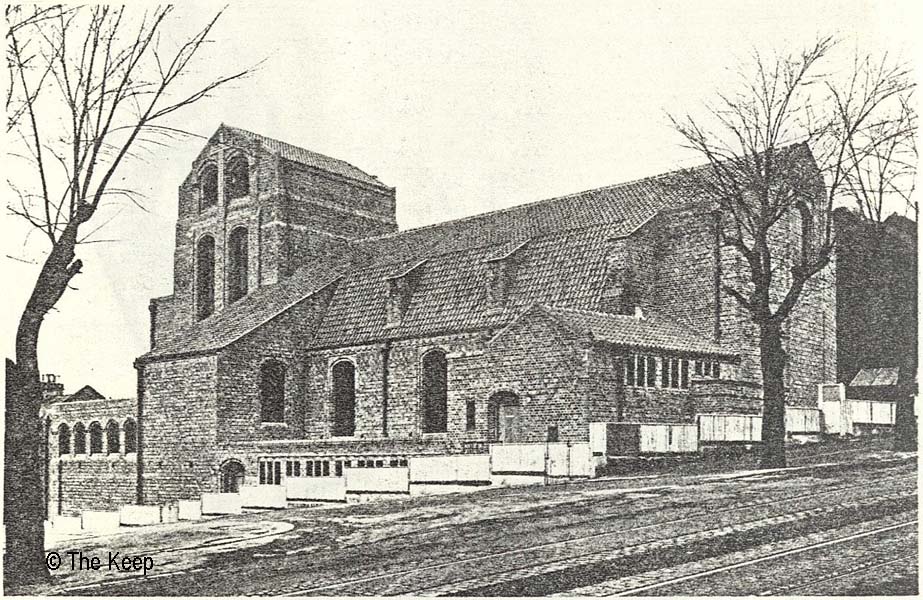

Drawing of the new St Wilfrid's Church. Keep Ref: BHBox7b/20

General. — Built for the Church of England as a memorial to Wilfrid Burrowes, Bishop of Chichester. The site is on a corner, two sides being closely built up, and falls steeply from north-east to south-west. It is not oriented, the sanctuary being at the west end. The total cost was £15,000 and the maximum seating is approximately 500.

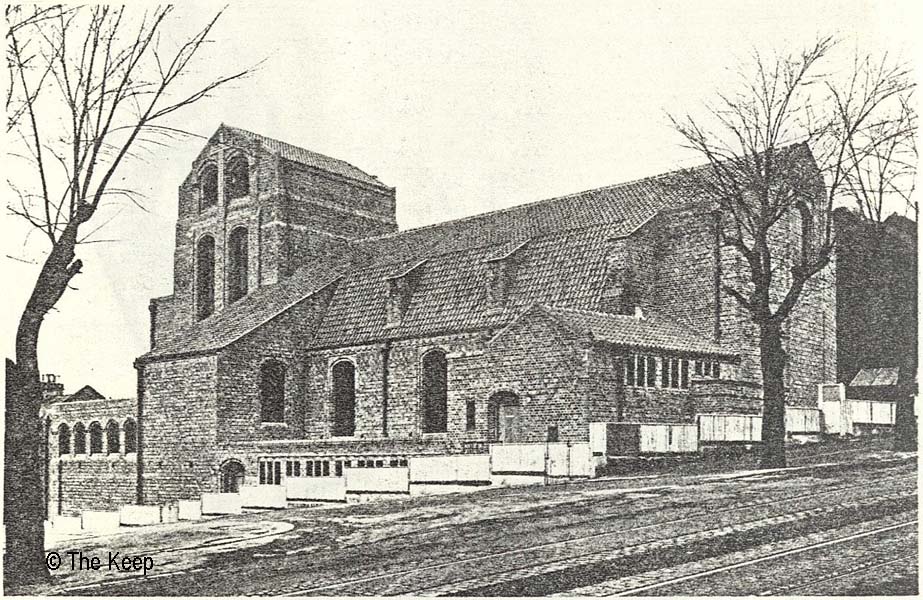

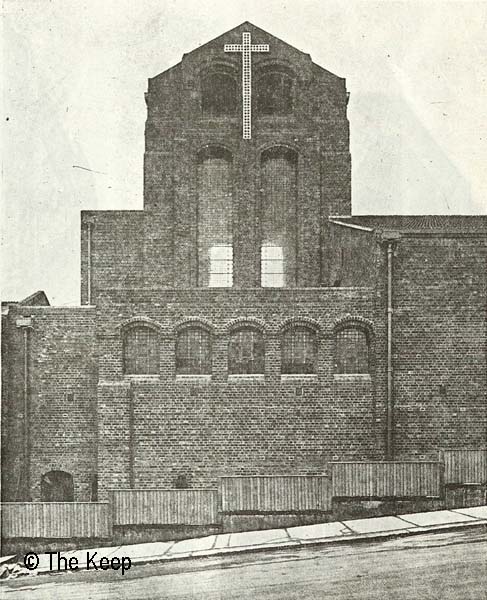

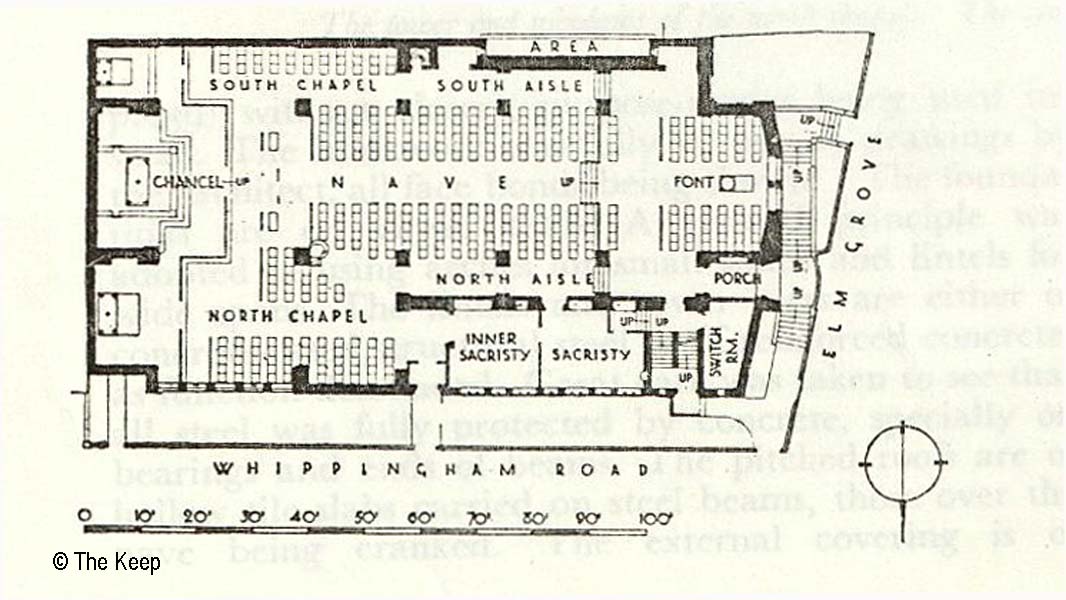

Plan of St Wilfrids Church. Ref: BHBox7b/20

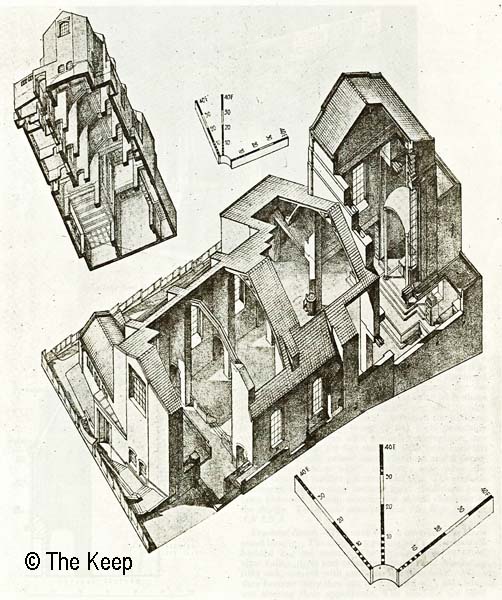

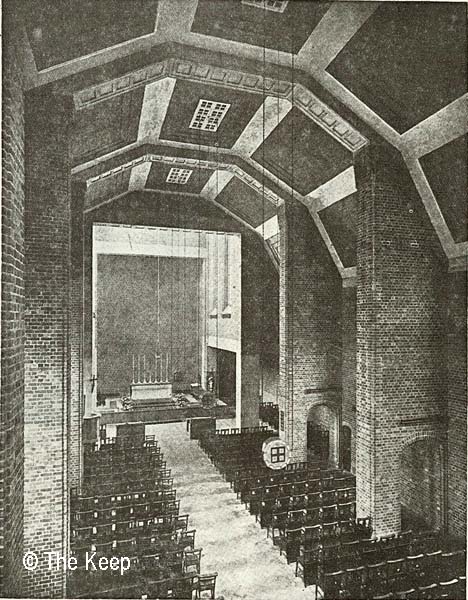

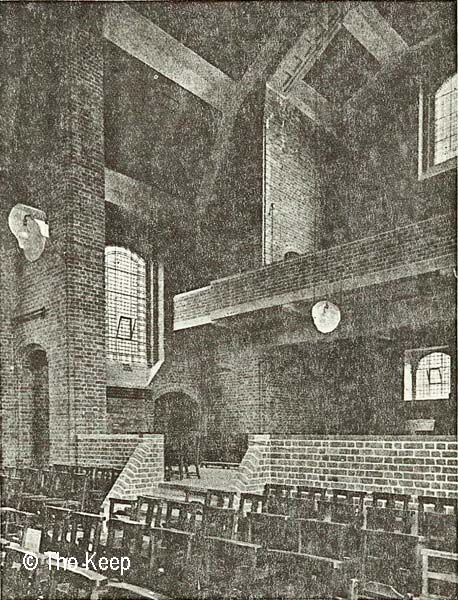

Form. — The slope of the site is such that the floor of the church has been arranged on two levels; there is also a gallery at the "west" end and a crypt or storage space lies under the sanctuary end. The general form of the building consists of a wide nave with passage aisles, pierced through the piers, abutting against a large tower. The tower, open for the greater part of its height, stands on reinforced concrete legs and has chapels on two sides and. on the long axis, an unwindowed recess in which the high altar stands. A baldacchino has been designed for the high altar. The sacristies form a low unit parallel with the nave.

Construction. — Resistance to fire and permanence were prime factors in the choice of materials. Walls generally consist of two g-inch skins of brick, connected by 9-inch cross walls, the size of the cavity varying up to 2 feet. The cavity is not ventilated but has a splayed concrete floor covered with bituminous sheeting carried through both walls. Facing bricks, inside and out, are local Keymer kiln stocks: main wall bricks are Warnham Common pressed. Lime mortar of hydrated lime was used throughout, except in foundations and copings; the work was flush-jointed.

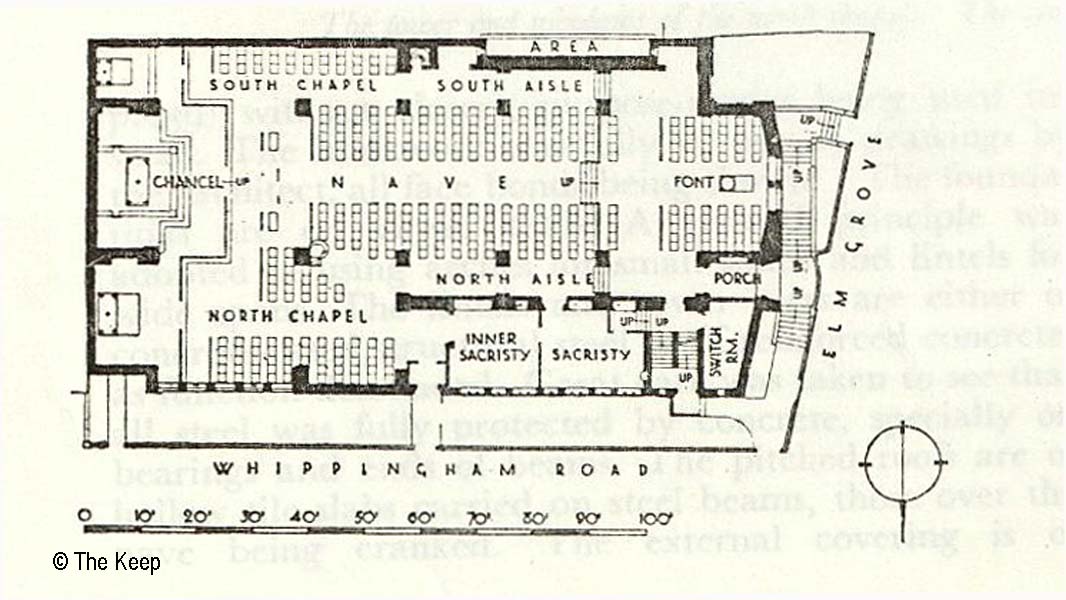

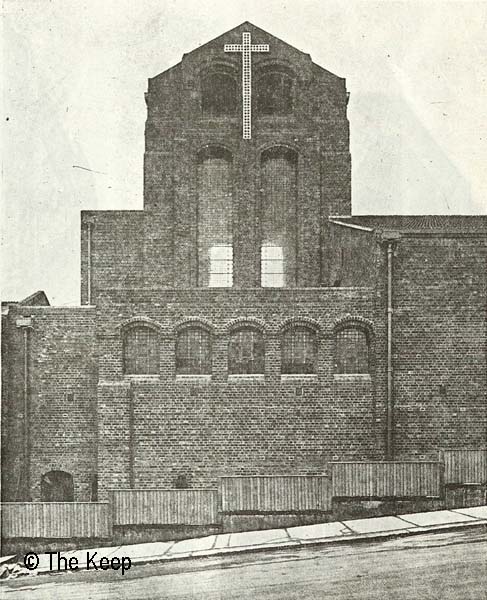

The tower and windows of the north chapel. The cross is of

4 inches by 4 inches blue tiles surrounded by gold mosaic. Keep

Ref: BHBox7b/20

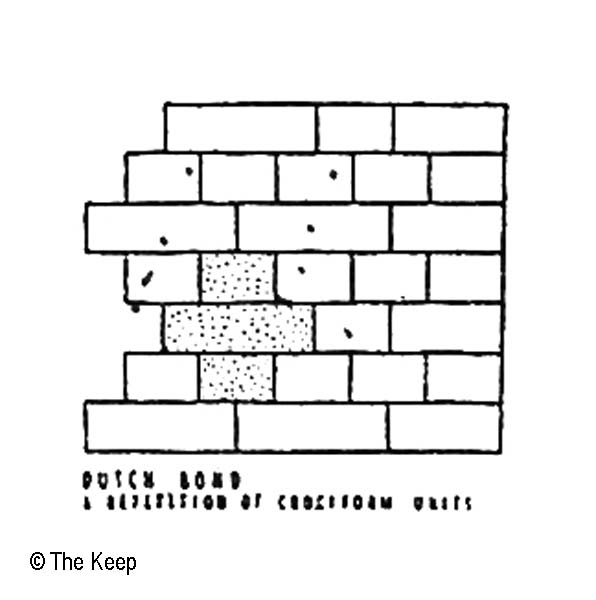

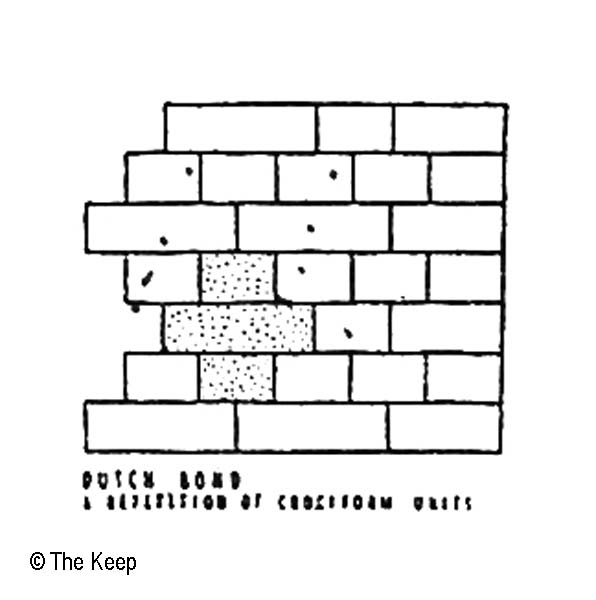

The bond is Dutch (see sketch below) without closers, purpose-made being used instead. The brickwork was fully set out on drawings by the architect, all face bonds being shown. The foundations are on virgin chalk. A general principle was adopted of using arches for small spans and lintels for wide spans. The lintels and tower piers are either of concrete-cased structural steel or of reinforced concrete, as function demanded. Great care was taken to see that all steel was fully protected by concrete, especially on bearings and ends of beams. The pitched roofs are of hollow tile slabs carried on steel beams, those over the nave being cranked. The external covering is of pantiles on battens nailed to patent fixing blocks in the concrete. Flat roofs are surfaced with a double layer of bituminous felt on 2-inch compressed cork insulating slabs. The concrete casing was left untouched from felt-lined shuttering; the aggregate was white gravel and sand with ordinary Portland cement, giving a concrete almost white. The consulting engineer was Mr. John Dewar.

The brick bond is Dutch bonding. Ref: BHBox7b-20

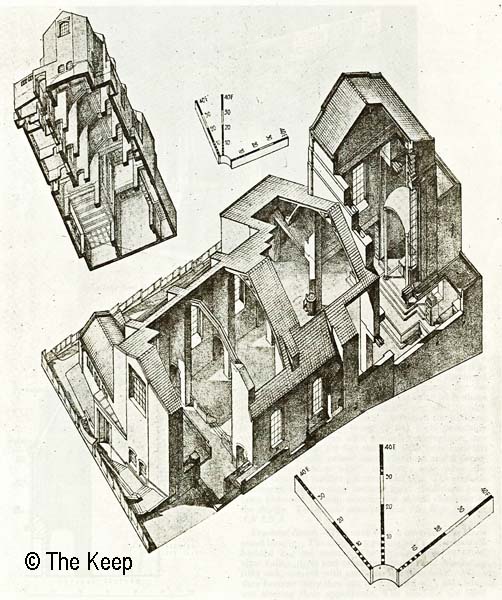

Three dimensional drawings of the church with sections cut away.

Keep Ref: BHBox7b/20

Acoustics. — The building came under the recent injunction of the Bishop of Chichester that acoustics were to be considered in all new church designs from the early stages. The site is a noisy one owing to trams and gear-changing of motor traffic. The noise was kept out by limiting the glass area on the "west" wall and also by a thorough sound-absorbing treatment on the underside of the hollow-tile roof. This consists of .an asbestos fibre material sprayed on with a special adhesive, the material being afterwards lightly trowelled or smoothed with a lath as desired. The natural colours have been used as part of the interior design, white asbestos being employed for soffits and styles, and blue-grey asbestos for the larger recessed panels. The cost of this material is about 10s. per yard (½ inch thick) and 18s. per yard (1 inch thick) in reasonably large areas. Although the building is large, the sanctuary being 50 feet high, preaching voice conditions, even with a small congregation, are good. For singing, the fact that the walls have been left without absorbent causes inter-reflections and a consequent reverberation which reinforces tone when the source of sound reaches a certain loudness. The acoustic treatment is interesting because good conditions have been obtained without altering the shrine character of the design. The acoustic consultant was Mr. Hope Bagenal, A.R.I.B.A.

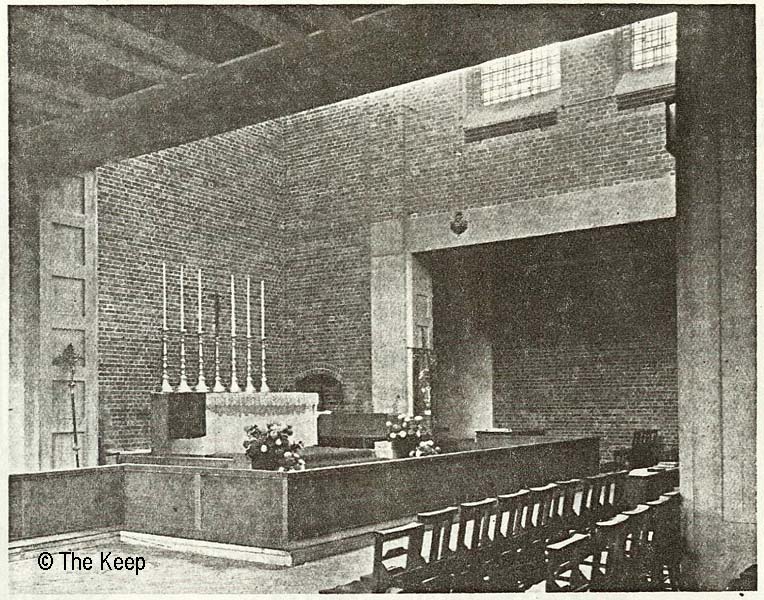

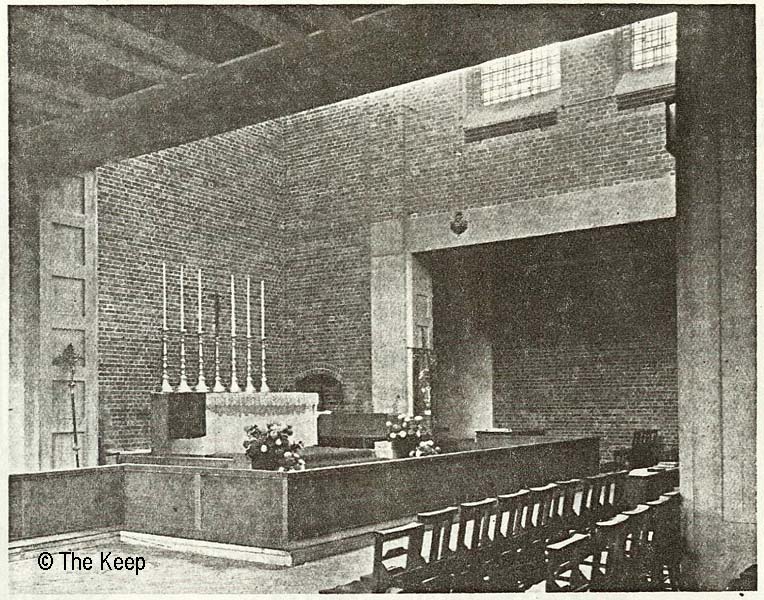

Looking from the north chapel across the chancel. The altar-rail encloses the three altars. Keep Ref: BHBox7b/20

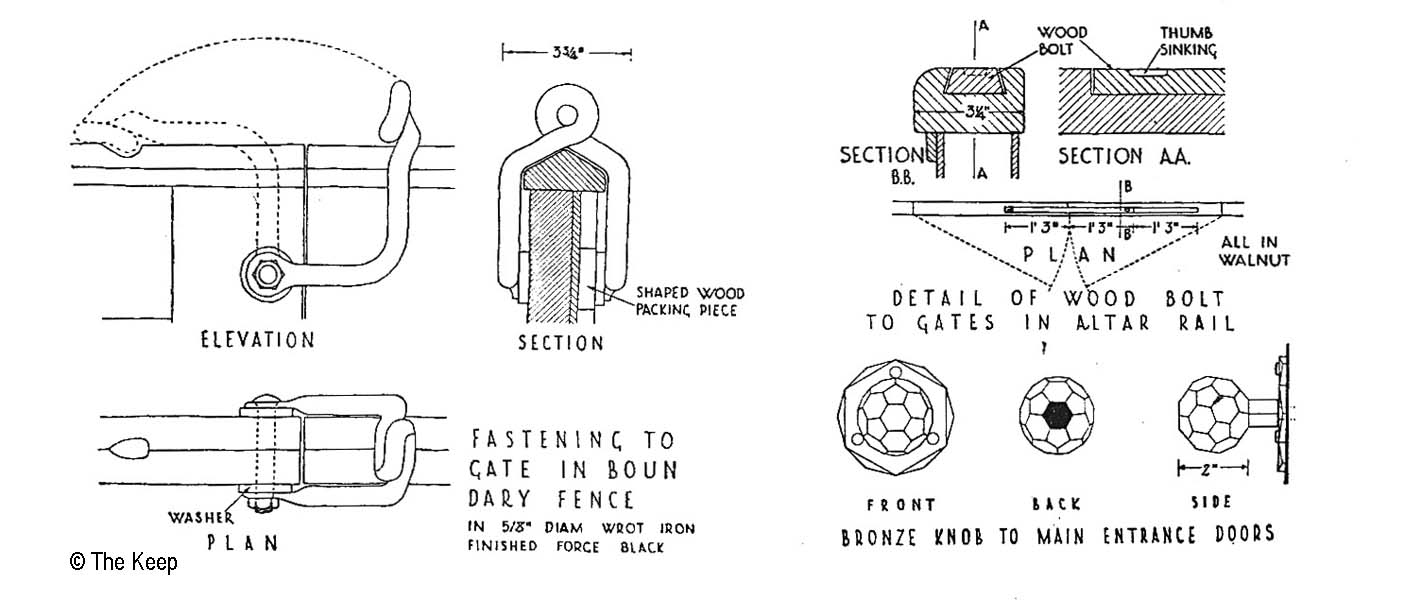

Structural Finish. — The nave floor is covered with Karri wood blocks. The sanctuary paving is of York stone slabs bedded in lime mortar. The sedilia, credence table, altar rails, pulpit and other furniture are in Australian silky oak, treated with ordinary washing soda. When they become dirty, they can be scrubbed with soda without altering their appearance. The windows are filled with simple pattern leaded lights glazed with a mixture of slightly obscured glass of varying tints. The outer doors are of teak and the inner of Australian walnut with rebated and felted edges (sectional detail below) which makes them draught-proof. The German silver cross and candlesticks on the south altar were the architect's design and gift.

Equipment. — Ventilation is by short inlets with slight upcast at window sill level and by means of extract grilles in the ceiling bays, connected by a trunk to a vertical flue in the tower. Lighting is by hanging reflectors in the nave, throwing the light of 200-watt pearl lamps towards the altar, which is also lit by two 150-watt floods near the ceiling of the tower. The lighting consultant was Mr. Waldo Mailland, A.R.I.B.A.

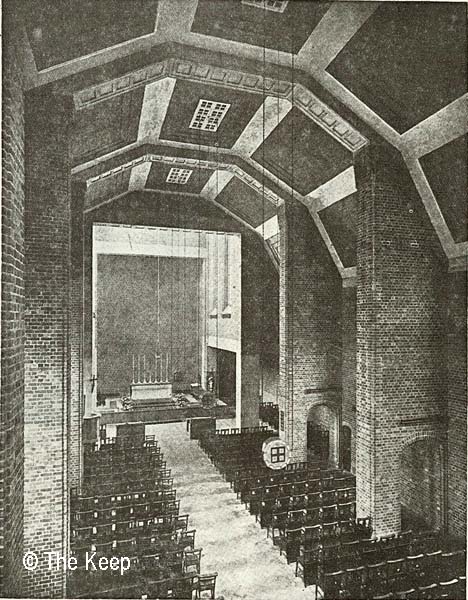

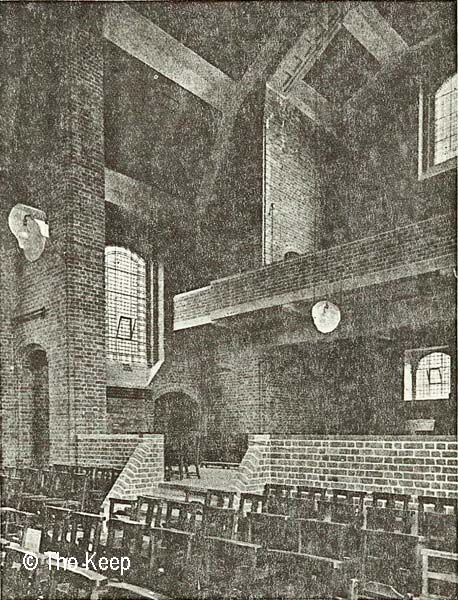

The nave from the gallery. A baldacchino has been designed for the high altar. Keep Ref: BHBox7b-20

The raised floor and gallery at the "west" end, seen from one of the aisle arches. Keep Ref: BHBox7b-20

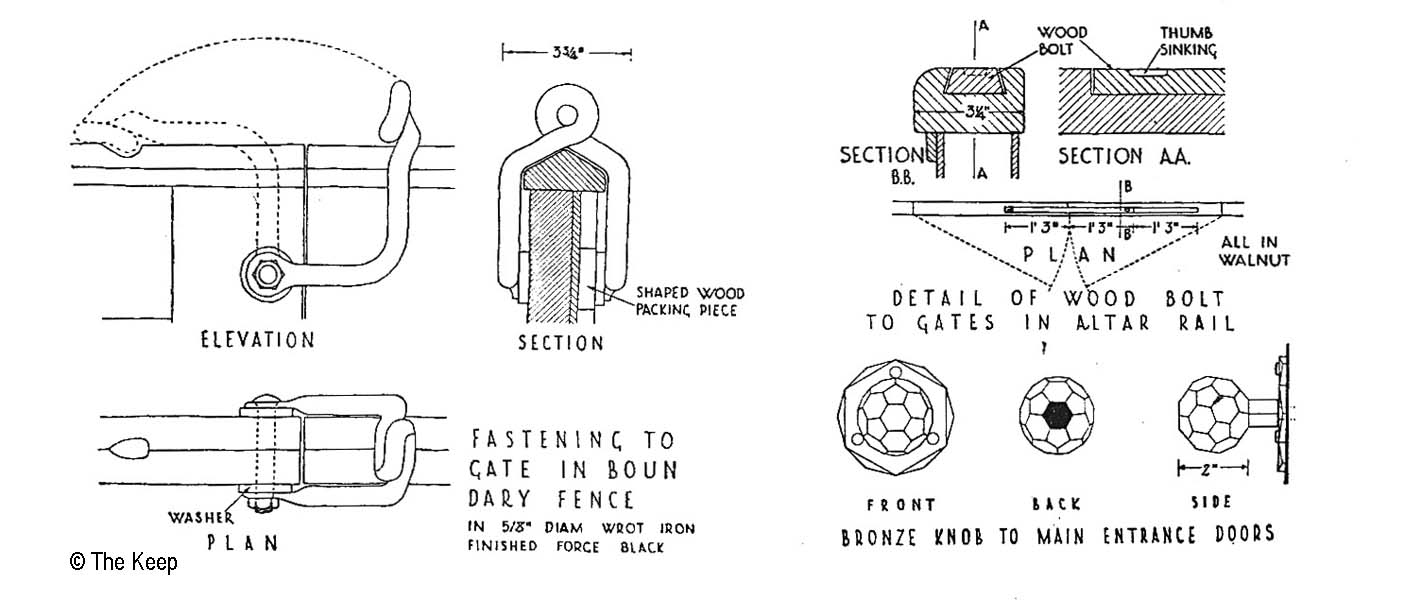

Details of some of the church fittings. Keep Ref: BHBox7b-20

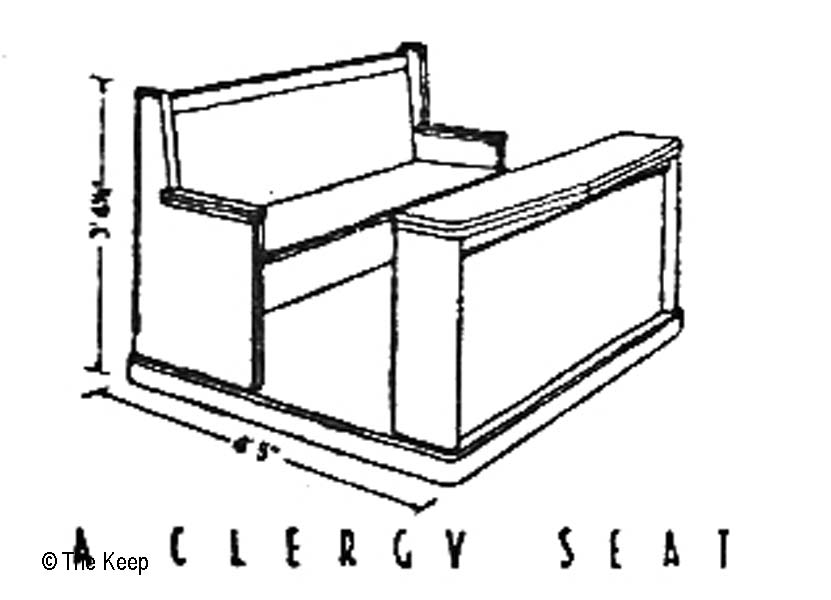

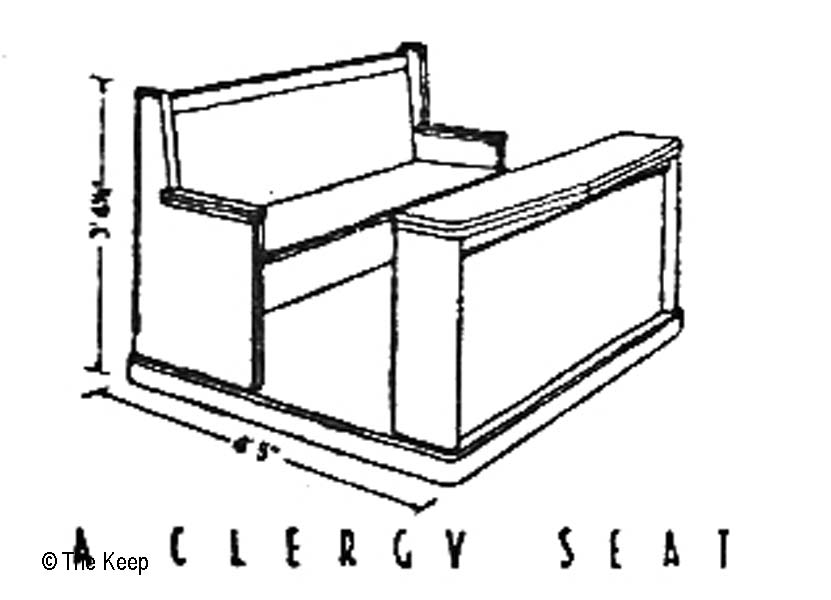

A Clergy Seat. Keep Ref: BHBox7b-20

Heating is by means of standard type 2-inch electrical tubular heaters with a loading of 60 watts per foot. These are placed where possible under windows to counteract down-draught and also on the undersides of rows of chairs which are battened into units, connection being by a heavy to a floor plug for each unit.

The total load is 71 kilowatts, of which 56 are used by the church interior, 16 being by the high level heating and 40 by the low level. The whole system is in three main sections, subdivided into groups of not more than 20 amps, loading each. The system has been designed to give an inside temperature of 60° to 62° when it is freezing outside. Current is purchased at ½d. a unit. The consulting engineer for the heating and lighting was Mr. William Maclntyre.

CONTRACTORS AND SUPPLIERS

GENERAL CONTRACTORS: George Lynn and Sons, Ltd.

STRUCTURE: Bricks and tiling, P. R. Skinner and Co., Ltd. Reinforced concrete and hollow tile construction, F. Bradford and Co., Ltd. Steelwork, Mattew. T. Shaw and Co., Ltd. Roofing felt and dampcourse, D. Anderson and Son, Ltd. Hydrated lime, The Cement Marketing Co., Ltd.

STRUCTURAL FINISH: Metal casements, door furniture and side altar candlesticks, James Gibbons, Ltd. Acoustic treatment, Newall's Acoustic Products, Ltd. Lead glazing, Whall and Whall, Ltd. Wood block flooring, Hollis Bros, and Co., Ltd.

STRUCTURAL EQUIPMENT: Electric lighting and heating, T. Clarke and Co., Ltd. Pulpit, sedilia, altar rails, etc., Betty Joel, Ltd. Internal metal light fittings and rainwater goods, Thomas Elsley, Ltd. Mosaic cross and piscina, Art Marbles, Stone and Mosaic Co., Ltd. Bell hanging, Mears and Stainbank. Lightning conductors, J. W. Gray and Son, Ltd. Temporary organ, J. W. Walker and Sons, Ltd. Iron staircase, F. A. Norris and Co., Ltd.

FURNITURE AND SUNDRIES: Chairs and kneelers, Mealing Bros., Ltd. Foundation stone carving, Esmond Burton. Safe, Hobbs, Hart and Co., Ltd. Magnetic hymn boards, Wm. Potter and Sons, Ltd.

From: The Journal of The Royal Institute of British Architects on the 13th January 1934.

ST. WILFRID'S CHURCH, BRIGHTON

Architect: H. S. Goodhart-Rendel [V-P.]

Architect: H. S. Goodhart-Rendel [V-P.]

Drawing of the new St Wilfrid's Church. Keep Ref: BHBox7b/20

General. — Built for the Church of England as a memorial to Wilfrid Burrowes, Bishop of Chichester. The site is on a corner, two sides being closely built up, and falls steeply from north-east to south-west. It is not oriented, the sanctuary being at the west end. The total cost was £15,000 and the maximum seating is approximately 500.

Plan of St Wilfrids Church. Ref: BHBox7b/20

Form. — The slope of the site is such that the floor of the church has been arranged on two levels; there is also a gallery at the "west" end and a crypt or storage space lies under the sanctuary end. The general form of the building consists of a wide nave with passage aisles, pierced through the piers, abutting against a large tower. The tower, open for the greater part of its height, stands on reinforced concrete legs and has chapels on two sides and. on the long axis, an unwindowed recess in which the high altar stands. A baldacchino has been designed for the high altar. The sacristies form a low unit parallel with the nave.

Construction. — Resistance to fire and permanence were prime factors in the choice of materials. Walls generally consist of two g-inch skins of brick, connected by 9-inch cross walls, the size of the cavity varying up to 2 feet. The cavity is not ventilated but has a splayed concrete floor covered with bituminous sheeting carried through both walls. Facing bricks, inside and out, are local Keymer kiln stocks: main wall bricks are Warnham Common pressed. Lime mortar of hydrated lime was used throughout, except in foundations and copings; the work was flush-jointed.

The bond is Dutch (see sketch below) without closers, purpose-made being used instead. The brickwork was fully set out on drawings by the architect, all face bonds being shown. The foundations are on virgin chalk. A general principle was adopted of using arches for small spans and lintels for wide spans. The lintels and tower piers are either of concrete-cased structural steel or of reinforced concrete, as function demanded. Great care was taken to see that all steel was fully protected by concrete, especially on bearings and ends of beams. The pitched roofs are of hollow tile slabs carried on steel beams, those over the nave being cranked. The external covering is of pantiles on battens nailed to patent fixing blocks in the concrete. Flat roofs are surfaced with a double layer of bituminous felt on 2-inch compressed cork insulating slabs. The concrete casing was left untouched from felt-lined shuttering; the aggregate was white gravel and sand with ordinary Portland cement, giving a concrete almost white. The consulting engineer was Mr. John Dewar.

The brick bond is Dutch bonding. Ref: BHBox7b-20

Three dimensional drawings of the church with sections cut away.

Keep Ref: BHBox7b/20

Acoustics. — The building came under the recent injunction of the Bishop of Chichester that acoustics were to be considered in all new church designs from the early stages. The site is a noisy one owing to trams and gear-changing of motor traffic. The noise was kept out by limiting the glass area on the "west" wall and also by a thorough sound-absorbing treatment on the underside of the hollow-tile roof. This consists of .an asbestos fibre material sprayed on with a special adhesive, the material being afterwards lightly trowelled or smoothed with a lath as desired. The natural colours have been used as part of the interior design, white asbestos being employed for soffits and styles, and blue-grey asbestos for the larger recessed panels. The cost of this material is about 10s. per yard (½ inch thick) and 18s. per yard (1 inch thick) in reasonably large areas. Although the building is large, the sanctuary being 50 feet high, preaching voice conditions, even with a small congregation, are good. For singing, the fact that the walls have been left without absorbent causes inter-reflections and a consequent reverberation which reinforces tone when the source of sound reaches a certain loudness. The acoustic treatment is interesting because good conditions have been obtained without altering the shrine character of the design. The acoustic consultant was Mr. Hope Bagenal, A.R.I.B.A.

Looking from the north chapel across the chancel. The altar-rail encloses the three altars. Keep Ref: BHBox7b/20

Structural Finish. — The nave floor is covered with Karri wood blocks. The sanctuary paving is of York stone slabs bedded in lime mortar. The sedilia, credence table, altar rails, pulpit and other furniture are in Australian silky oak, treated with ordinary washing soda. When they become dirty, they can be scrubbed with soda without altering their appearance. The windows are filled with simple pattern leaded lights glazed with a mixture of slightly obscured glass of varying tints. The outer doors are of teak and the inner of Australian walnut with rebated and felted edges (sectional detail below) which makes them draught-proof. The German silver cross and candlesticks on the south altar were the architect's design and gift.

Equipment. — Ventilation is by short inlets with slight upcast at window sill level and by means of extract grilles in the ceiling bays, connected by a trunk to a vertical flue in the tower. Lighting is by hanging reflectors in the nave, throwing the light of 200-watt pearl lamps towards the altar, which is also lit by two 150-watt floods near the ceiling of the tower. The lighting consultant was Mr. Waldo Mailland, A.R.I.B.A.

The nave from the gallery. A baldacchino has been designed for the high altar. Keep Ref: BHBox7b-20

The raised floor and gallery at the "west" end, seen from one of the aisle arches. Keep Ref: BHBox7b-20

Details of some of the church fittings. Keep Ref: BHBox7b-20

A Clergy Seat. Keep Ref: BHBox7b-20

Heating is by means of standard type 2-inch electrical tubular heaters with a loading of 60 watts per foot. These are placed where possible under windows to counteract down-draught and also on the undersides of rows of chairs which are battened into units, connection being by a heavy to a floor plug for each unit.

The total load is 71 kilowatts, of which 56 are used by the church interior, 16 being by the high level heating and 40 by the low level. The whole system is in three main sections, subdivided into groups of not more than 20 amps, loading each. The system has been designed to give an inside temperature of 60° to 62° when it is freezing outside. Current is purchased at ½d. a unit. The consulting engineer for the heating and lighting was Mr. William Maclntyre.

CONTRACTORS AND SUPPLIERS

GENERAL CONTRACTORS: George Lynn and Sons, Ltd.

STRUCTURE: Bricks and tiling, P. R. Skinner and Co., Ltd. Reinforced concrete and hollow tile construction, F. Bradford and Co., Ltd. Steelwork, Mattew. T. Shaw and Co., Ltd. Roofing felt and dampcourse, D. Anderson and Son, Ltd. Hydrated lime, The Cement Marketing Co., Ltd.

STRUCTURAL FINISH: Metal casements, door furniture and side altar candlesticks, James Gibbons, Ltd. Acoustic treatment, Newall's Acoustic Products, Ltd. Lead glazing, Whall and Whall, Ltd. Wood block flooring, Hollis Bros, and Co., Ltd.

STRUCTURAL EQUIPMENT: Electric lighting and heating, T. Clarke and Co., Ltd. Pulpit, sedilia, altar rails, etc., Betty Joel, Ltd. Internal metal light fittings and rainwater goods, Thomas Elsley, Ltd. Mosaic cross and piscina, Art Marbles, Stone and Mosaic Co., Ltd. Bell hanging, Mears and Stainbank. Lightning conductors, J. W. Gray and Son, Ltd. Temporary organ, J. W. Walker and Sons, Ltd. Iron staircase, F. A. Norris and Co., Ltd.

FURNITURE AND SUNDRIES: Chairs and kneelers, Mealing Bros., Ltd. Foundation stone carving, Esmond Burton. Safe, Hobbs, Hart and Co., Ltd. Magnetic hymn boards, Wm. Potter and Sons, Ltd.

From: The Journal of The Royal Institute of British Architects on the 13th January 1934.